ABOUT US

We have developed a line of high quality, industry leading centralizer products for both drilling and casing.

Backed by several decades of product development experience within the Oil & Gas industry, the VYKOR team has a proven track record of innovation and successful product commercialization throughout various organizations.

We are a solid group of industry professionals with years of hands on field operations, professional engineering and project management experience. A team who has authored and been named on various oilfield service industry patent submissions — part of our professional commitment is to develop technologies that lead change in the industry and develop products the industry needs to supplement ongoing operations.

PRODUCTS

VYKOR’s forming technology produces a precision manufactured shape resulting in a centralizer that is rigid, has dynamic flow characteristics and is the toughest centralizer on the market.

Titan Steel Body Centralizer – Titan SB

The Titan SB is a one-piece steel body centralizer that is mechanically formed to evenly produce fins to centralize casing for uniform cementing jobs. Hard-facing can be applied in highly abrasive well bore applications.

Application Benefits:

- Designed for use in casing running, casing reaming and casing drilling applications.

- Extremely durable construction.

- Reduces casing string torque and drag.

- Simple installation at well site.

- Better centralization for cementing in vertical, deviated and horizontal wells.

Design and Features:

- Unique design provides superior durability and rigidity capable of withstanding extreme downhole loads while maintaining standoff under large side forces.

- Steel body construction can withstand rough downhole conditions.

- Fins and body are formed as a single integral component by the press forming process.

- Helical fin design ensures circulation, hole cleaning and even cementing.

- Tungsten carbide hard facing can be applied to the fins for additional wear protection in extremely abrasive formations for casing drilling and casing reaming applications.

- Compatible with all drilling fluids.

- Steel centralizers are intended to “float” between the casing couplers, or can be limited in travel between mechanically fastened Stop Rings.

Steel Body Stand-Off-Band – Titan SOB

The Titan SB is a one-piece steel body stand-off-band that is mechanically formed to evenly produce fins to centralize casing for uniform cementing jobs.

Application Benefits:

- Designed for use in casing running applications.

- Extremely durable construction.

- Reduces casing string torque and drag.

- Simple installation at well site.

- Better centralization for cementing in vertical, deviated and horizontal wells.

Design and Features:

- Unique design provides superior durability and rigidity capable of withstanding extreme downhole loads while maintaining standoff under large side forces.

- Steel body construction can withstand rough downhole conditions.

- Fins and body are formed as a single integral component by the press forming process.

- Helical fin design ensures circulation, hole cleaning and even cementing.

- Compatible with all drilling fluids

- Steel centralizers are intended to “float” between the casing couplers, or can be limited in travel between mechanically fastened Stop Rings.

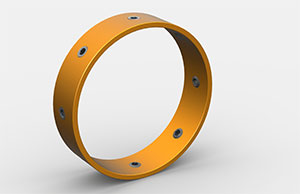

Titan Steel Stop Ring

Steel Stop Ring

Application and Design Benefits:

- Designed for use in Casing Running, Casing Reaming Casing Drilling applications where centralizers are installed and require placement of the centralizer in a fixed location

- Extremely Durable Construction with more robust than industry standard jam screws to ensure once installed, they remain fixed

- Simple Installation at well site

Centralizer Spec Sheet

| Nominal Casing Size |

Fin OD | Number of Fins |

Fin Angle |

||

|---|---|---|---|---|---|

| (inch) | (mm) | (inch) | (mm) | ||

| 4-1/2 | 114.3 | 6 | 152 | 4 | 27 deg |

| 4-1/2 | 114.3 | 5 7/8 | 149 | 4 | 27 deg |

| 4-1/2 | 114.3 | 5 3/4 | 146 | 4 | 27 deg |

| 4-1/2 | 114.3 | 5 5/8 | 143 | 4 | 27 deg |

Casing Stand-Off Band Spec Sheet

| Nominal Casing Size |

Fin OD | Number of Fins |

Fin Angle |

||

|---|---|---|---|---|---|

| (inch) | (mm) | (inch) | (mm) | ||

| 4-1/2 | 114.3 | 6 | 152 | 6 | 40 deg |

| 4-1/2 | 114.3 | 5 7/8 | 149 | 6 | 40 deg |

| 4-1/2 | 114.3 | 5 3/4 | 146 | 6 | 40 deg |

| 4-1/2 | 114.3 | 5 5/8 | 143 | 6 | 40 deg |

SERVICES

VYKOR’s Energy Products offers a line of casing and drill pipe centralizers and accessories.

For special applications for non-standard drilling, reaming, casing exits and centralization, where custom product development is required, Vykor may be able to engineer a solution and manufacture products for a single application as well as for an entire product line for customer’s ongoing drilling and cementing needs.

Vykor is committed to ongoing technical development. We are not limited to drilling and have experience in surface equipment and completions equipment as well.

Calgary, Alberta, Canada

+1 (403) 560-2931

per@angman.ca